PLC / PAC

Ideally, the structure of a PLC program should follow that of the object model, including the separation of equipment and the procedures which control the equipment. A structured, object oriented approach will highly improve maintainability and scalability.

Recent experience with:

Schneider M340, M580

Siemens S7-ET200S, S7-1200 and S7-1500

Allen Bradley Control/Compact/MicroLogix

Omron CJ1

Wago 750-series

SCADA

Modern SCADA systems are packed with features such as redundancy, distribution of services, web-based / mobile clients, open communication standards (such as OPC UA) and .NET programming. Equally important are security and the quality of the user interfaces with more and more emphasis on situational awareness. So from an architecture and configuration perspective, building a large SCADA system requires a breadth of knowledge. Over the last 35 years I have worked on all these aspects, implementing various systems such as SattGraph, FactoryLink, PVSS, WinCC, ClearSCADA, CitectSCADA, Intouch and more recently AVEVA System Platform with Intouch OMI frontend.

Other services I can provide in relation to SCADA systems are the design and implementation of standards as well as the development of bespoke Apps in Wonderware System Platform using Microsoft .NET and Windows Presentation Foundation technology.

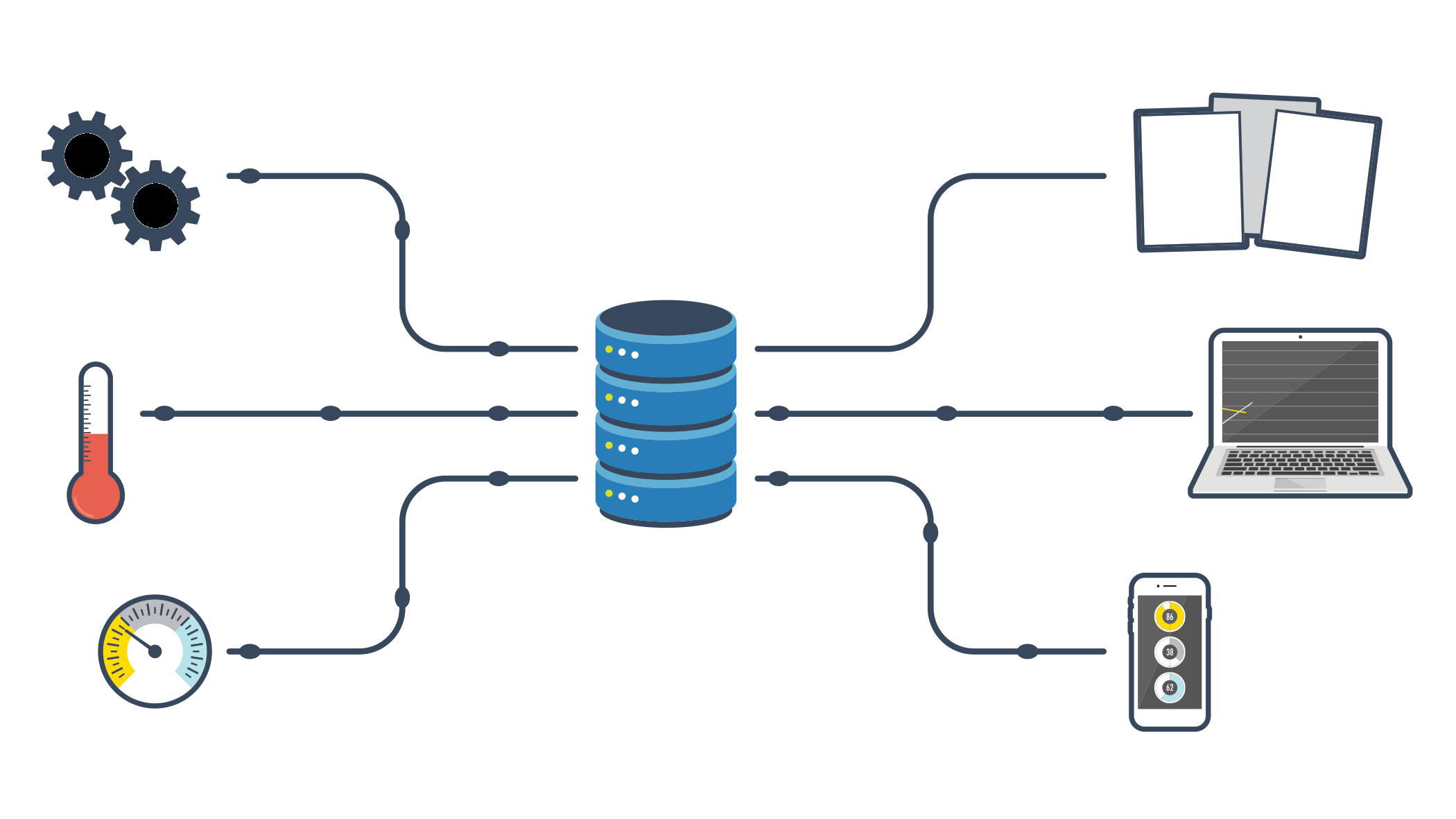

Historian / Databases

Data Historians are used to record instrument readings and track and trace operator activities for the purpose of e.g. data analytics (like trending), gathering production and maintenance information and quality control. Although configuring a Data Historian requires knowledge in relation to data source connectivity, setting up data points (e.g. deadbands), redundancy and maintenance, the basic function of the system is reasonably straight forward, i.e. the storage of data points in a time series database.

However, the next stage, which is generating information from the data and presenting this information in the right format to the right people, is most often a lot more complex. My experiences in this area are the following:

Reporting (such as Ministry Of Health compliance reporting for the water industry) using tools like SQL Reporting Services and Crystal reports;

Ad-hoc analytics using typical Data Historian client tools like trend engines;

Overall Equipment Efficiency (OEE) reporting;

Transact-SQL Querying;

Telemetry

Communication with remote sites can be achieved in many ways:

Wired connections such as Fiber Optic, ADSL and VDSL in combination with VPN;

IP-based VHF/UHF radio systems;

Cellular networks; (using either VPN over APN’s or private APN’s)

Rural broadband (WiFi);

Microwave connections;

And more recently IOT type networks like Sigfox, LoRaWan, NB-IOT and LTE-M

There are many aspects to consider in relation to the choice of network such as cost, cyber security, bandwidth, availability, reliability etc. Through my involvement in numerous telemetry projects I can help selecting the best telemetry system for a specific application.

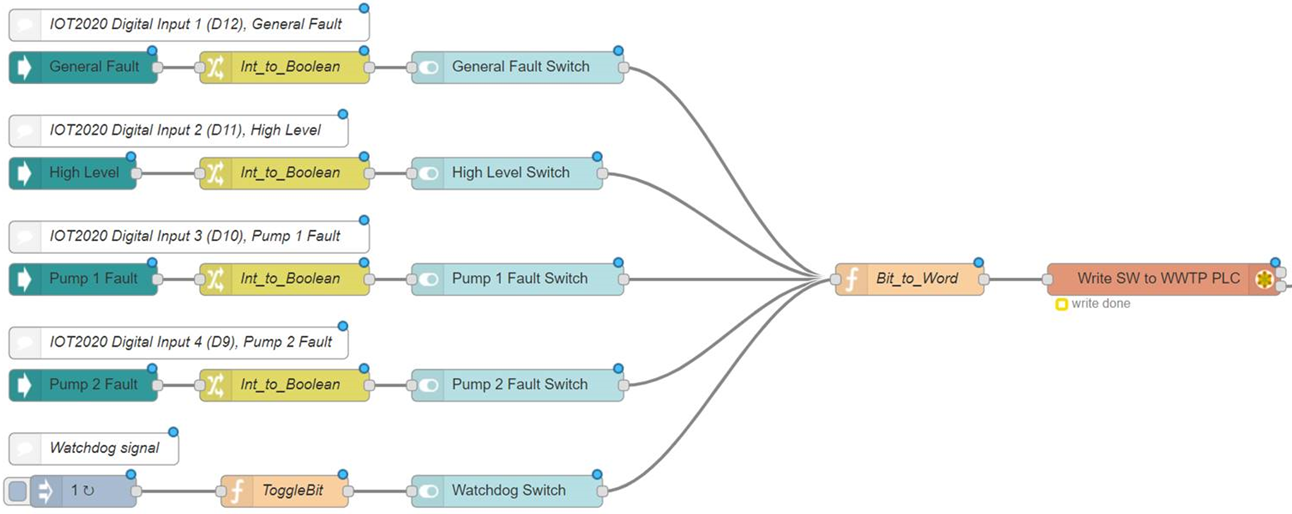

Industrial Internet of Things

Machine-to-machine communication has been around for many decennia, but on the back of developments around e.g. cloud computing, mobile technologies and machine learning, the Internet of Things has brought some very useful techniques and tools to the domain of industrial control. Networks like LoraWAN or NB-IOT in combination with programming environments like Node-Red provide new ways to move data directly from a sensor to the control system and/or directly to a cloud service.

I’m continuously updating my skills to be able to make optimal use of these new technologies.