FEED

The Front End Engineering Design, which comes after the conceptual design, focuses on the technical requirements as well as rough investment cost for the project. Value engineering is often a part of this process to help improve the budget of the project. In most cases, a FEED is a multi-disciplinary activity involving a lot of collaboration with the end-client, other engineers and contractors. The main outputs of the control system engineering activity are the scope of the project, the system technology selection, system configurations, cost estimates and a project schedule

Object Modelling

To create structure in a control system design, however small, it is often useful to build an object model of the system. By decomposing the system into well-defined building blocks ( such as areas, process cells, units and equipment ) and placing these objects in a hierarchical tree, a clear representation of the entire system will appear. The object names used in the model will generally be the same as the designations showing on the Process and Instrumentation Diagrams.

The object model can be used for a raft of activities such as requirement and change management, PLC code generation, SCADA configuration and documentation.

Over the years, I’ve developed my own tools to help me with defining object models and associated functionality.

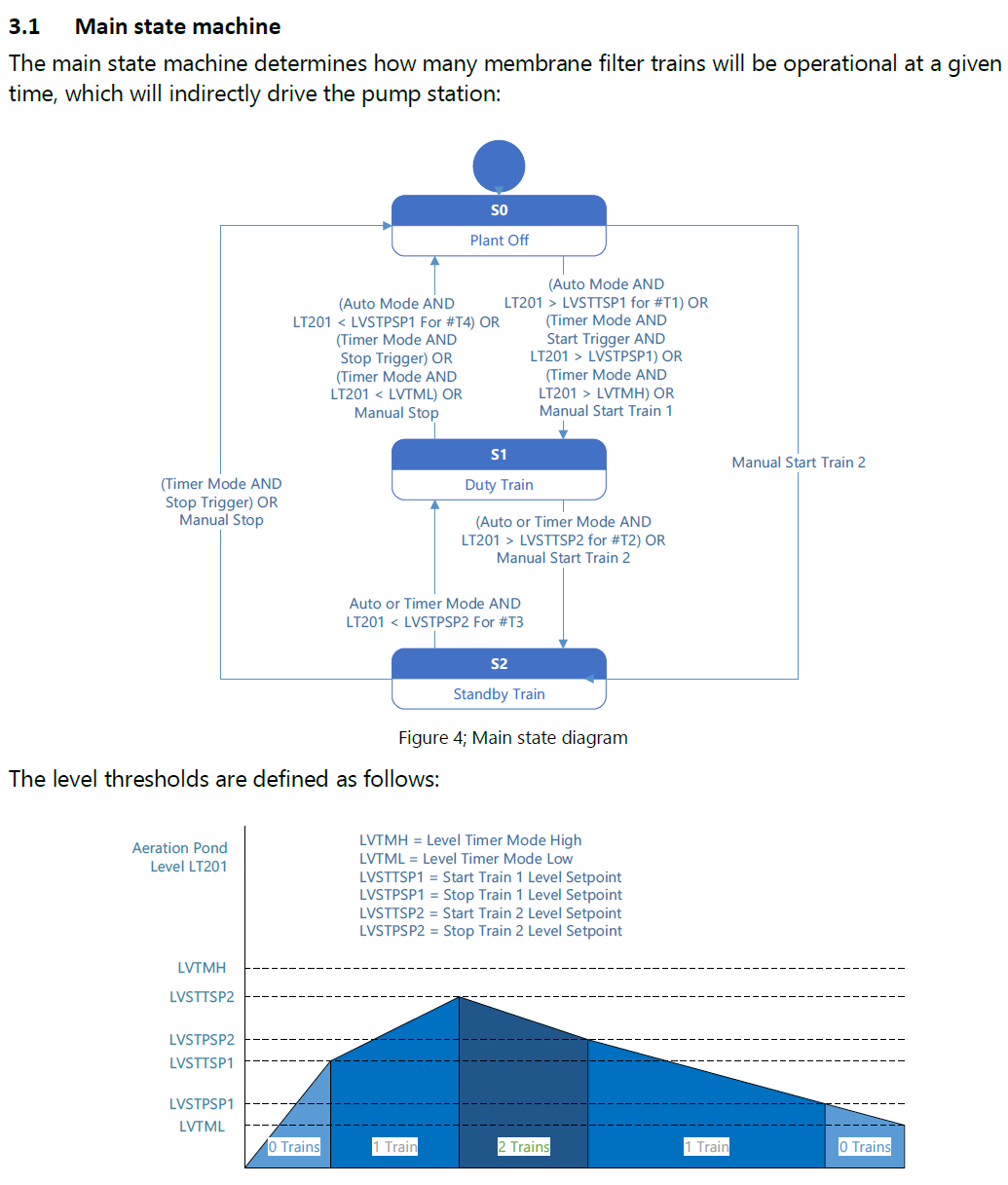

Functional Design

This process focuses on what is to be done, and less on how it happens. It specifies the logical flow of the system, its inputs and outputs, its data organisation, the applicable business and processing rules, and how it should appear to the user. The output of this activity is the Functional Design Specification or FDS.

Through collaboration and coordination with the client and other disciplines (such as mechanical and process engineering) I can develop the entire functional design for the project.

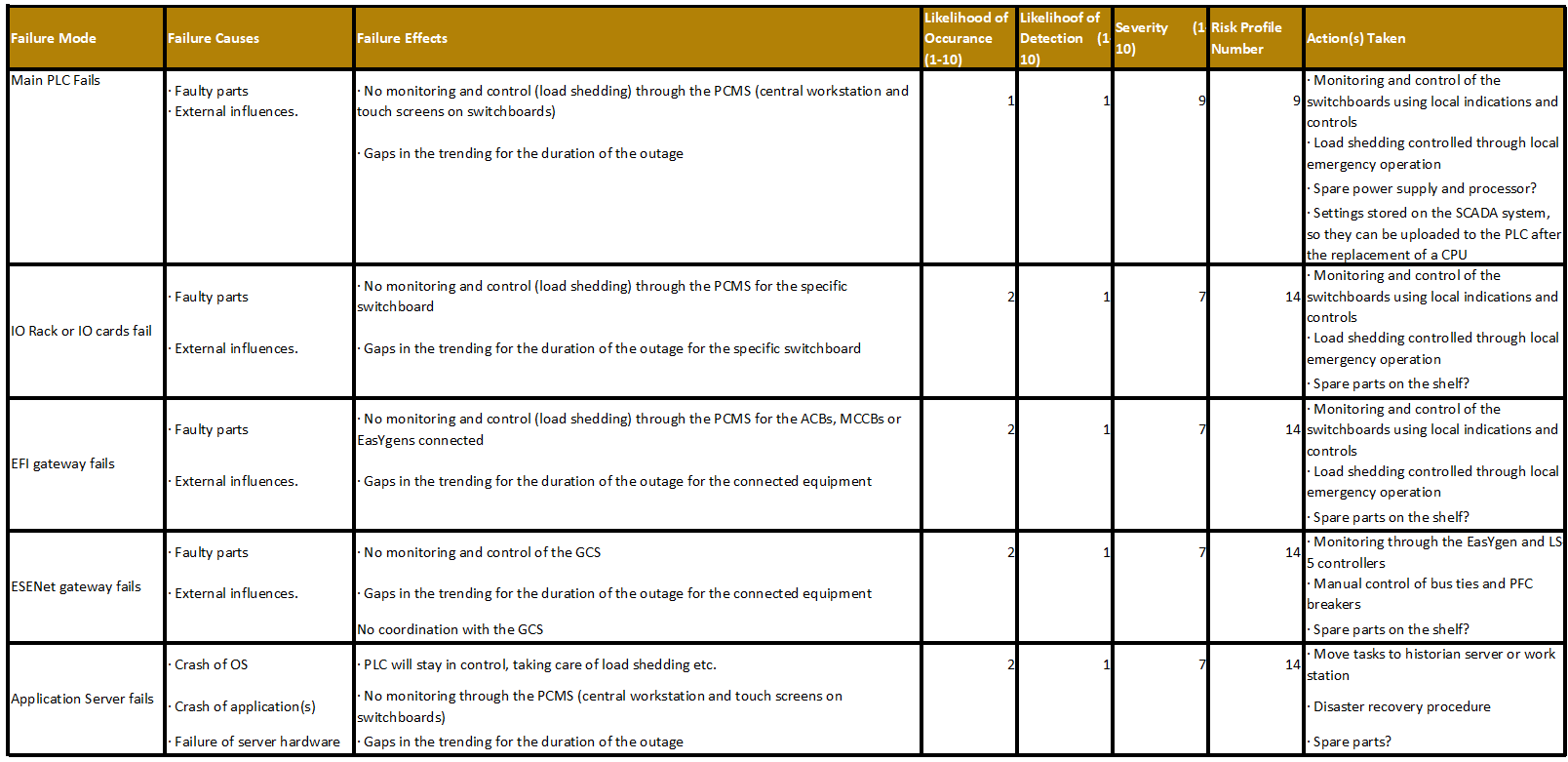

Failure Modes and Effects Analysis & Risk Analysis

A FMEA is a methodology to establish;

Failure modes (What could go wrong?);

Failure causes (Why would the failure happen?);

Failure effects (What would be the consequences of each failure?);

The likelihood of a failure;

Actions to reduce the occurrence of a failure;

FMEA is an excellent tool to predict which part of the process has the highest chance of failure and also to determine how that risk can be reduced. Generally it leads to solutions that are more robust and have lower risk to cause harm.

Development of Standards

If an control system covers multiple sites or areas with identical or similar control functionality or when it is likely that a control system will grow over the lifespan of the installation, developing standards can save a lot of time, both during the development phase and the maintenance phase of the project. A standard will generally describe the following:

Tagging conventions (sometimes using existing standards like ISA5.1)

Communication structures;

PLC functions and methodologies;

SCADA objects including their visual aspects;

data storage and reporting;